Equipment sterilisation is a critical concern for any dental practice. It’s part of the reconditioning process for instruments, which includes the following steps:

- Equipment collection

- Disinfection

- Washing

- Rinsing

- Drying

- Inspection and maintenance

- Packaging

- Sterilisation

- Traceability

- Storage

Interestingly, devices developed by Mocom, such as Tethys H10, carry out steps 2 – 3 – 4 – 5 in a fully automatic way, saving assistant’s time and making the whole process faster and more efficient.

The 3 classes of steam autoclaves

Autoclaves are used for the sterilisation of surgical instruments and equipment. There are three classes,

Class B autoclaves, the top performing types, able to sterilise all sterilisable instruments used in dental surgeries. Class S (S stands for “specified”) and Class N (N stands for “naked”) autoclaves

The following is a brief overview of the 3 cycles performed by the B, S and N autoclaves:

Type B cycles

Used for porous materials and hollow and solid instruments, with double wrapping, single wrapping or without wrapping. This cycle ensures maximum safety for the sterilisation of all types of instruments used in a dental surgery.

Type S cycles

Used for types of equipment and/or instruments as declared by the producer. This cycle offers an acceptable level of safety only for the instruments listed in the manual.

Type N cycles

Used only for solid, unwrapped instruments. This cycle offers acceptable guarantees only whenever an instrument is used immediately afterwards, as sterile storage is not possible.

An autoclave, also known as a steriliser, is part of the essential equipment of a dental practice. Since the dentist is required to sterilise their instruments, these devices are considered medical devices whose manufacturers must provide use and maintenance instructions which must be strictly followed.

Saturated steam autoclaves must guarantee a less than 1/1,000,000 probability that a contaminating microorganism can survive. Once sterilised, the equipment must be properly packaged and stored in aseptic conditions for a given time, until it is next used.

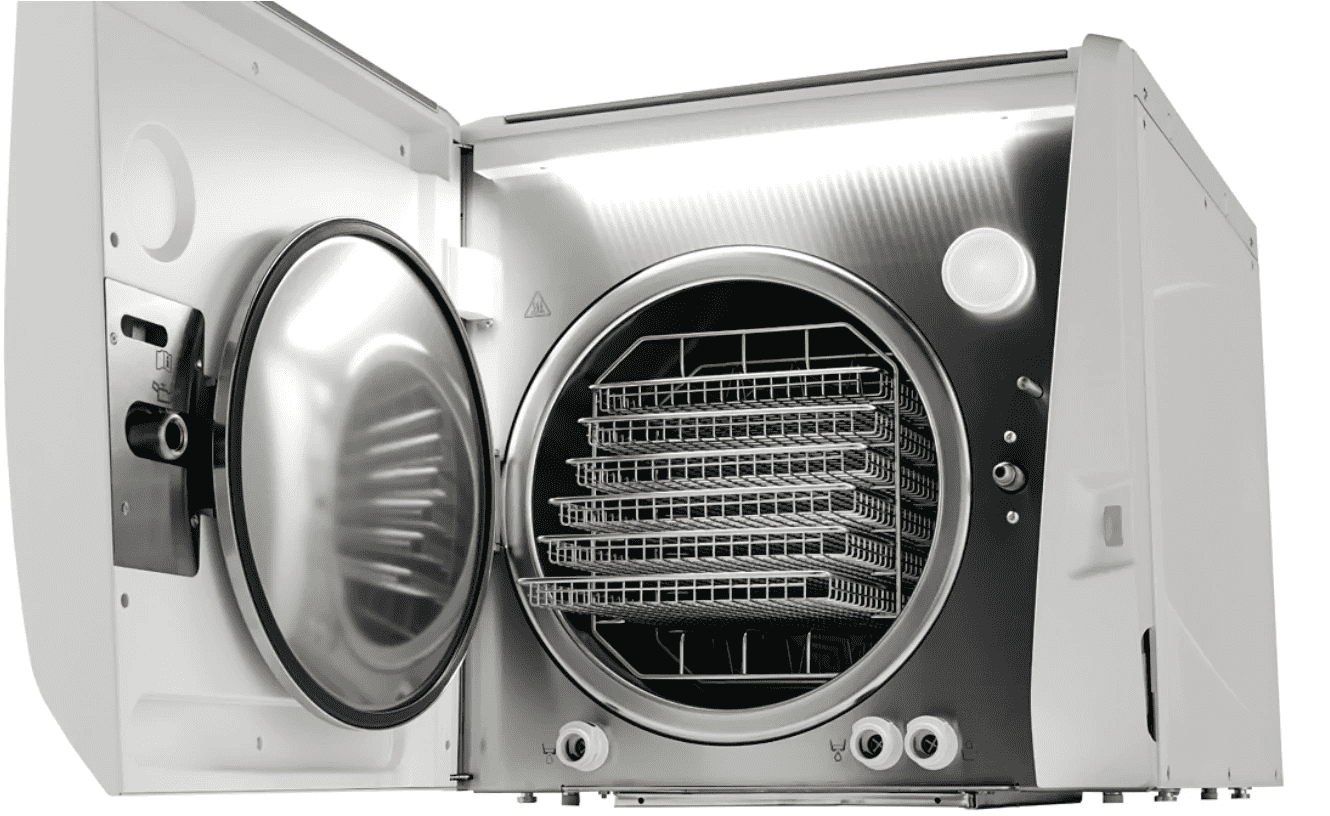

How does a Class B autoclave work?

Inside the sterilisation chamber, where the instruments to be sterilised are placed, there is air. As the sterilising agent, in this case, steam at 134°C, must come into direct contact with the surfaces of the materials, it is advisable to replace the contained air with steam. This is done during a phase known as fractional pre-vacuum, followed by a dramatic increase in pressure which is maintained at 2.1 bar for the required sterilisation time. The final step is negative pressure drying to minimise the level of humidity in the sterilisation chamber.

Class B autoclave maintenance

While the quality of the appliance guarantees its performance, it is essential, however, to strictly follow the maintenance schedule.

Every day clean the external surfaces, the door and its seal. The water tank should be disinfected and the internal filters cleaned thoroughly every week.

Our advice is to always carefully follow the device manufacturer’s recommendations.

Periodically, autoclaves will need maintenance, from the simple replacement of the door seal to a general technical overhaul.

How to choose an autoclave that is just right for you?

Assuming that it will be a Class B autoclave, a few factors should be considered in order to make the right choice i.e.:

- the number of persons available for equipment reconditioning operations in the dental practice

- the volume of instruments used in the practice (number of handpieces or other items to be sterilised)

- the number of dental chairs in use at the surgery/practice

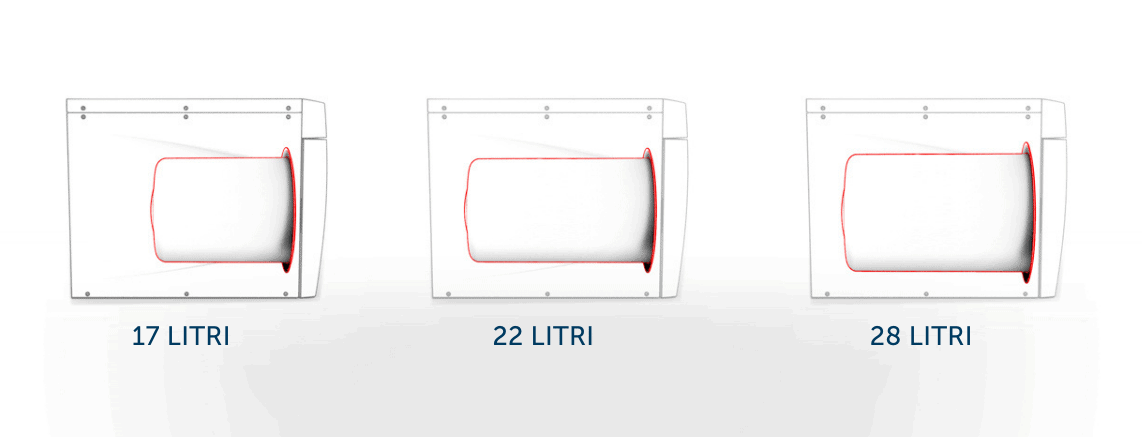

We should also bear in mind that the autoclaves in the Mocom range, while all having exactly the same external footprint – which is very useful if a fixed space is available – have three different capacities: 17, 22 and 28 litres.

As an example, here are some common cases:

In a surgery with 2 dental chairs, one assistant in charge of sterilisation and a large set of instruments, we would recommend a 28-litre autoclave used once after the morning therapy sessions and once in the evening.

In a surgery with 2 dental chairs, two or three assistants, a limited supply of handpieces and equipment to be sterilised, an ideal solution would be an autoclave with a capacity of 22 litres (even just 17 litres) to be able to run frequent cycles throughout the day.

In a surgery with at least 4/5 dental chairs, several dentists and assistants and a large volume of instruments to be reconditioned, we recommend at least one large autoclave with an operation schedule to be followed throughout the day and a small 17-litre autoclave for emergencies.

Small or large Class B autoclave?

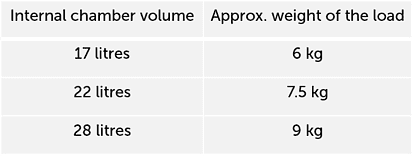

To make this decision, it can be useful for dentists to review market trends over the past 5 years. The trend is now towards larger autoclaves. This chart better shows capacities and loading volumes.

Fewer and fewer 17-litre models are used for a reason: 3 cycles are needed to sterilise 18 kg of material, while 2 cycles are enough with the 28-litre model. Since process times are not very different, the speed and lower consumption ensured by the higher-capacity autoclave model have an impact on user preferences.

Additionally, the 28-litre model is only approximately 20% more expensive than the 17-litre autoclave. For this reason, rarely do we find today a dental practice equipped with the smaller model only.

View the products here:

Article by, Apr 20, 2022 | written by: Mocom | Editorial Staf